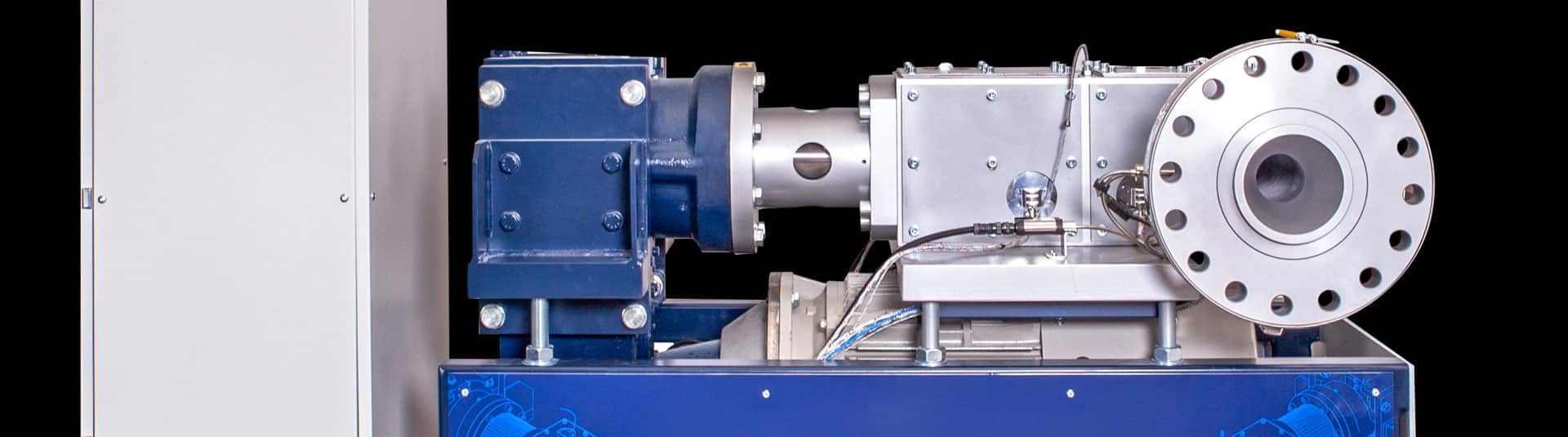

INNOVATIVE, ONE-OF-A-KIND TECHNOLOGY DESIGNED TO MAKE THE WORK OF RECYCLERS FASTER, MORE EFFECTIVE AND CHEAPER.

SPA is a revolutionary machine: a pump that allows you to easily transport plastic material melted by the extruder to the filter without using gears. SPA, in fact, operates with a single screw and requires very little maintenance. The ideal solution for anyone looking for the highest quality of the final result while significantly lowering management costs.

THE SECRET IN A SCREW

Standard gear pumps used to recycle plastic material are very sensitive because the contamination contained therein can damage them easily. For this reason, not only is constant maintenance required, but often also the installation of a safety filter to protect the pump, with a significant economic outlay, both for the purchase of the machinery and the interventions required for its operation. Not forgetting that gears must be periodically replaced by the operator, a further operating disadvantage.

Choosing the innovative SPA screw pump, on the other hand, ensures significant savings, because the management costs are greatly reduced – there is no need for maintenance, nor is it necessary to buy a second protective filter or expensive replacement gears that the operator needs to have on hand for replacement.

SIMPLIFIED USE, OUTSTANDING RESULTS

Operating it is incredibly easy. A gear pump is, in fact, much more complex to operate, while SPA is easy to use and does not require periodic replacements by operators. It can also be used both before and after the filter, and is also perfect for double filtration needs.

- Before the filter: it allows you to protect the twin-screw extruder used for the production of compounds.

- After the filter: it allows you to stabilise the pressure of the material and also increase the productivity of the filter and extruder.

SPA combines the highest level of engineering design, that has always been a signature feature of FIMIC technologies, with the highest quality of the construction materials, to offer a superior, reliable and high-performance product.

At the same time, the innovative operation of the FIMIC screw pump guarantees recyclers major savings in operating costs, as well as excellent end material.

ALL THE BENEFITS OF SPA

WHY CHOOSE SPA

Three letters to describe our latest creation, intended to change the operating methods of anyone who recycles plastic materials.

SPA stands for Screw Pump Antonio, named after Antonio Canaia, who over twenty years ago created the first self-cleaning automatic filter, a revolutionary idea for the time, that provided the impetus for the great FIMIC innovations. Important challenges that bear our mark of excellence, always with a view to improving the recycling of plastic materials, making it more efficient, interpreting the demands of the current market.

Find out why SPA is different!

THE FILTRATION SPECIALISTS

Our screw pumps adapt to any system, whether new or existing.

We study the most suitable size & screw design to meet any production & pressure control requirements, based on the type of plastic material to be processed and the hourly throughput target.

Contact us and tell us what you need: we will work out the best solution for you.